Electric. Built just right.

international emv series

- 25,999 and 33,000 lbs.

- MV60E

- 107.9" BBC, 40" BA

- Day Cab

- 217", 236", 254" & 272"

- 4x2

Single Rear Axle (4x2)

• Dana Spicer 23,000 lb.

REAR SUSPENSION

- 21,000 lb single axle with shocks

- IROS Air Suspension

- Dana Spicer I-Beam 12,000 lb.

- Spring, Parabolic Taper Leaf: 12,000 ilbs.

- Heat Treated Alloy Steel 120,000 PSI

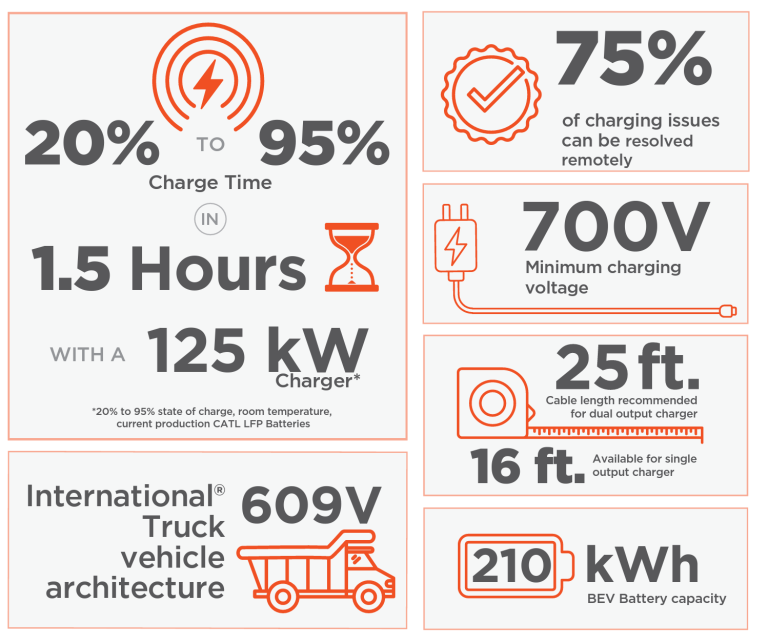

- High Voltage - 210kWh Lithium

- Iron Phosphate with dedicated

- HVAC system

- 608 volt operating voltage

- LED Headlights

- Air Brakes with ABS, 4 channel

- Electronic Stability Program with

- Traction Control

- TRW/Ross Power

- Direct Drive Electric Motor

- Peak Motor Torque - 1,700 ft-lbs

- Continuous Motor Torque - 738 ft-lbs

- Continental

- 6.83

WHAT MAKES THE EMV™ SERIES UNIQUE?

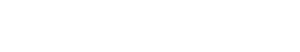

Built on the same proven foundation we use in our diesel MV, we made some key placement changes including the batteries and battery controller; the motor controller and motor; the radiator and Battery Thermal Management System (BTMS); as well as the air tanks and air bag suspension.

Key features of the new eMV include:

-210kWh battery pack

-135-mile range

-Electric drive motor

-Industry-leading 3 levels of regen braking

-AC/DC charging and capability with up to 125kWh DC fast charge

-VTG capability and a new full digital display

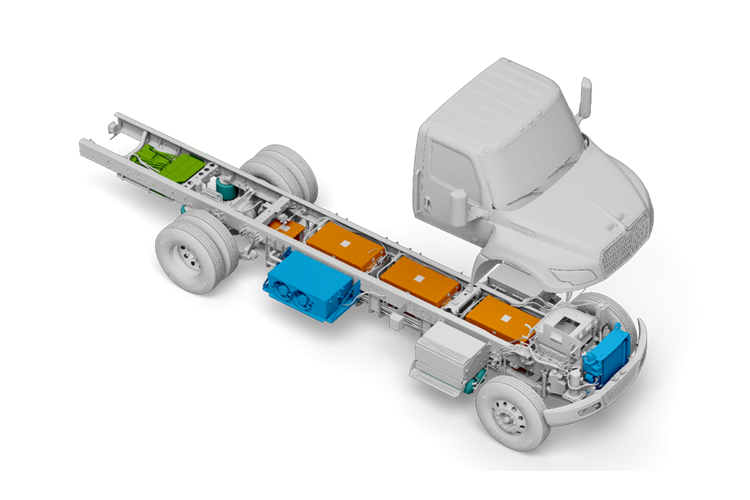

Zero Emissions Maintenance Schedule

It’s no secret electric vehicles require less maintenance. With substantially fewer parts, an electric motor simply does not have the maintenance or service requirements of an internal combustion engine. Plus, thanks to regenerative braking, the standard brakes last much longer between service intervals.

TAKE THESE OFF YOUR SERVICE PLATE

- No engine oil maintenance

- No transmission maintenance

- No fuel filters

- No turbos, no EGR, no Injectors

- No engine air filters, no MAF, no O2

- No aftertreatment

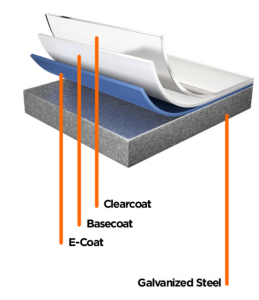

E-COAT PAINT PROCESS

ANTI-CORROSION THAT'S ANTI-COMPROMISE

Longevity is the head of the hammer. Every eMV Series cab assembly is dipped into an electrostatically applied primer as part of a rigorous paint, sealing, and coating process that provides superior corrosion and fade resistance – backed by a 5-year perforation corrosion warranty.

STEEL SACTUARY

FOR STRENGTH, SAFETY, AND COMFORT

The eMV Series cab wraps your crew in high-strength, low-allow (HSLA) reinforced, cold-rolled steel construction that combines the corrosion resistance of aluminum with the world-class fit, finish, and strength of steel. The result is a larger, quieter, more protective interior with air and water-tight seals.

The Intercoat Chemguard can be thought of as a self-healing layer of skin on our galvanized steel. This interactive, chrome-zinc, phosphate coating is used on floor and toe kick panels to help extend integrity and allow surface cuts, scratches, and perforations to maintain corrosion protection.

The optional Line-X floor protection, comprised of polyurethane and polyurea, creates a protective tray on the cab floor that contains spills, as well as any natures elements that make their way inside.

CHARGING

Building out a charging solution that’s appropriate for today but flexible enough to grow as you grow, can be a complicated process. We’re here to make that process as smooth as possible by working side-by-side through site planning and engineering, AC and DC charger installation, site management, equipment certification and financing for both vehicles and infrastructure.